AISI 347 by Taashvi Special Alloys

A standout product in the ever-changing world of metallurgy and specialty alloys is Taashvi Special Alloys' AISI 347. Taashvi Special Alloys' dedication to innovation and quality is demonstrated by AISI 347, an alloy designed to withstand the demanding requirements of high-temperature applications. Superior performance at high temperatures and resistance to corrosion are key features of this sophisticated version of stainless steel.

One of the families of austenitic stainless steels, AISI 347, stands out for having niobium (columbium) in its composition. Because of this calculated addition, the alloy is now more resistant to sensitization after extended exposure to high temperatures, which makes it a great option for use in the nuclear, aerospace, and petrochemical industries.

Key Features of AISI 347 by Taashvi Special Alloys:

01 High Temperature Stability: Because of its remarkable resilience at high temperatures, AISI 347 is a good choice for applications where exposure to prolonged heat is essential.

02 Corrosion Resistance: The corrosion resistance of the alloy guarantees life and dependability under demanding operating conditions, particularly in harsh settings.

03 Sensitization Resistance: Because of the niobium component, AISI 347 is able to successfully prevent sensitization, which is a common issue with stainless steel alloys that are periodically subjected to high temperatures.

04 Weldability: The alloy's outstanding weldability and ease of fabrication make it ideal for a variety of engineering tasks where reliable and efficient construction is required.

05 Versatility in Applications: Strong performance in harsh environments is required in a variety of industries, and AISI 347 finds flexible applications in anything from petrochemical processing equipment to high-temperature exhaust systems in aerospace engineering.

06 Improved Mechanical Characteristics: AISI 347 offers a balance of strength, ductility, and toughness, contributing to its suitability for diverse engineering applications.

Coil / Sheet /Plate Specification

Dimensions : ASTM, ASME, AISI, DIN, BIS

Thickness : 0.50mm - 100mm

Size : 1000 mm x 2000mm, 1220mm x 2440mm, 4' x 8', 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Form : Shim Sheet, Perforated Sheet, Profile Cut,

Seamless & Welded Pipes & Tubes Specification

Specification : ASTM, ASME, DIN, NFA, JIS.

Thickness : 4.0mm - 100mm.

Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size : 1/2" OD to 8" OD.

Length : Cut length, Fix length, Single Random, Double Random & Required Length.

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pancake Coils, Hydraulic Tubes.

End : Plain End, Beveled End, Threaded End.

Type : Seamless & Welded Pipes & Tubes.

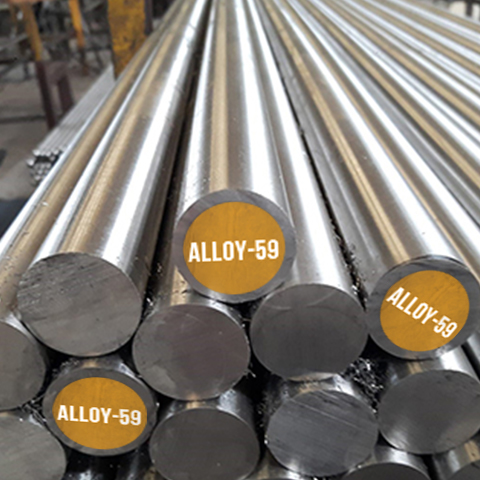

Round Bar Specification

Dimensions : ASTM, ASME,AISI, API.

Size : 5 mm to 500 mm

Length : from 2.00mm to 6.35mm (0.078" to 0.25") dia.

Finish : Bright, Black, Polish, Forged

Form : Round Bar, Square, Hexagon

Condition : Cold Drawn & Polished Cold Drawn, Centerless Ground Bars & Polished

Other Services : Machining (CNC), Centerless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Seamless & Welded Pipes & Tubes Fittings Specification

Specification : ASTM, ASME, DIN, NFA, JIS.

Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Form : Elbow, Tee, Reducer, Stub End, End Cap, Pipe Nipple, Weldolet,

End : Beveled End, Threaded. Plain End,

Type : Seamless & Welded Pipe & Tubes Fittings, Buttweld Fittings & Dairy Fittings.