FASTENERS MANUFACTURING

- Home

- FASTENERS MANUFACTURING

Contact us

- address 13/21, Office No. 124, Seth Virchand Umarsey Building, 1st Floor, Panjarapole 3rd Lane, Mumbai

- phone+91-7678041137 (24/7 Support Line)

+91-898066460 (WhatsApp) - emailtaashvispecialalloys@gmil.com

ENQUIRY NOW

FASTENERS MANUFACTURING by Taashvi Special Alloys

One brand stands out as a light of excellence in the complex world of industrial manufacturing, where endurance and precision are crucial: Taashvi Special Alloys. Leading the way in the production of fasteners, Taashvi Special Alloys has made a name for itself by continuously providing premium, tailored solutions to satisfy the changing demands of many industries. The business has established a reputation for producing cutting-edge fasteners that are the foundation of several applications in a wide range of industries because of its unwavering dedication to innovation, dependability, and precision.

Fastener Manufacturing

We are proud to be one of the last few fastener manufacturers left in the India. Based in Mumbai, we are dedicated to the design, advice, prototyping and manufacture of all types of male threaded fasteners from 4mm up to 200mm long, M1.5 to M18, in all popular metals – also available in the imperial equivalent. See our product range for a comprehensive table of products.

We are a key supplier to the automotive, aerospace, telecommunication, civil engineering and security sectors, to name but a few. With a wealth of experience, we can offer our customers a unique design, development and trial service; this is achieved through having our own in-house tool room, wire drawing, manufacturing and testing facilities. We are very proud of our setup, and if you have 30 minutes available, we welcome you to pop down or up (depending on where you’re based) to see our extensive plant of machines and diverse tooling room: Click here to request a site tour.

We operate systems that meet the requirements of ISO 9001:2015 and we are certified. We can offer full traceability on all parts and all accompanying quality documentation including ISIRs, FMEAs and PPAP Level 3

Fastener Manufacturing Process

Raw material inspection and storage

Casting / Forging

CNC machining (Facing, grooving)

Heat treatment

Form, fit & finish, dimensional inspection

Coating to prevent rust (Ex.geomet coating)

Thread rolling

Surface finish (Grinding)

Packaging

Our Capabilities

Our product range is extensive and includes many standard and non-standard parts supplied in accordance with BS/EN/DIN/ISO, or any other recognised industry standards.

Our expertise lies in the manufacture of:

- “SEMS” screws and captivated washer assemblies

- double ended studs

- tri-lobular and paint clearing threads

- bolts and general threaded fasteners

- self-tapping and wood screws

- bespoke security fasteners including all tamper-proofs

Our Process

Heading Process

Cold forging (or cold forming) is a process that takes cold heading quality wire on heading machines which is cut to required lengths. The “cut off” is transferred through a series of dies (the more complex the part, the greater the number of dies), which produces a “headed blank”. This part of the process determines the size and length and the head configuration i.e. countersunk, cap, pan etc. The recess is also formed at this stage i.e. socket, 6-lobe, pozi etc.

- specialised forgings

- cap screws

- security screws

Threading Process

Thread rolling machines feed the headed blank through a hopper and rails, passes it through a set of dies which form rather than cut the thread geometry. This process produces a thread form that is inherently far stronger and has a better grain flow than a cut thread. This part of the process determines the pitch and major/minor diameter of the tread form.

All parts can be offered with various plated or surface protected finishes.

These include:

- Zinc with colour options

- Chemi-Black

- Phosphating

- Most organic finishes

- Nickel-Chrome

- Thread lock sealing/patches

- Mechanical

Quality

Quality is paramount at Forward Fastener Manufacturing; we have invested hugely in our state-of-the-art inspection lab and optical sort machines to continually monitor our KPIs on parts-per-million. From the initial APQP with our quality engineers we can offer warranty, ISIR and full PPAP level 3 and all our products can be fully traceable all the way back to the raw material.

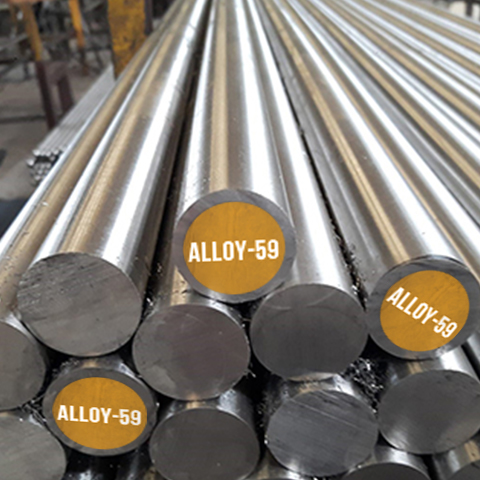

Material Availability

These include:

- Stainless Steel

- Duplex Steel

- Super Duplex Steel

- Titanium

- Tantalum

- Nickel Alloy

- Hastelloy

- Inconel

- Monel

- Nitronic

- Invar

- Copper Nickel