Hastelloy C276 Manufacturer & Supplier of Bars, Pipes, Plates & Flanges in Mumbai, India

Looking for a metal that won’t give up in the harshest environments? Meet Hastelloy C276. At Taashvi Special Alloys, we know how challenging it can be to find a material that resists corrosion, heat, and stress all at once. That’s why we offer Hastelloy C276, a high-performance alloy trusted across the chemical, marine, and power industries.

Whether you need material for heat exchangers, reactors, pipes, or fittings, Hastelloy C276 delivers unmatched reliability and longevity. With its excellent resistance to oxidizing and reducing agents, it performs where other metals fail. We supply Hastelloy C276 in plates, rods, tubes, wires, and custom components, manufactured to strict global standards and ready for your most demanding applications.

Key Features and Benefits of Hastelloy C276

- Exceptional resistance to acidic, oxidizing, and reducing environments

- Strong protection against pitting, crevice corrosion, and stress corrosion cracking

- High mechanical strength and dimensional stability at elevated temperatures

- Weldable and formable, suitable for precision components

- Long-lasting performance in harsh chemical processing environments

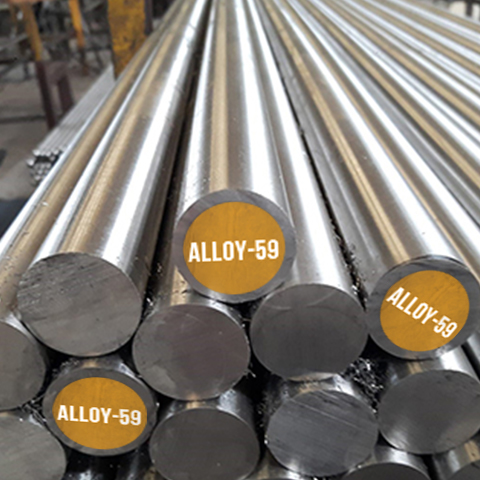

Available Forms of Hastelloy C276 at Taashvi Special Alloys

- Plates & Sheets

- Rods & Bars

- Pipes & Tubes

- Wires & Strips

- Forged Fittings

- Fasteners (Nuts, Bolts, Washers, etc.)

We also offer custom sizes and machining services to suit your project needs.

Applications / Uses of Hastelloy C276

- Chemical Processing Plants

- Marine Engineering

- Power Generation & Nuclear Reactors

- Pollution Control Equipment

- Pulp & Paper Manufacturing

- Heat Exchangers, Scrubbers, Vessels, and Reactors

- Pharmaceutical and Food Processing Equipment

Technical Specifications

- Standards: ASTM B575, B622, B619, B626

- Plates: Thickness from 0.5 mm to 100 mm

- Rods/Bars: Diameter 5 mm to 150 mm

- Pipes/Tubes: OD 6 mm to 100 mm

- Condition: Annealed, Pickled, Polished, Cold Drawn

- Temperature Tolerance: Performs up to 1040°C in oxidizing environments

Chemical Composition of Hastelloy C276

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | Balance |

| Molybdenum (Mo) | 15.0 – 17.0 |

| Chromium (Cr) | 14.5 – 16.5 |

| Iron (Fe) | 4.0 – 7.0 |

| Tungsten (W) | 3.0 – 4.5 |

| Cobalt (Co) | ≤ 2.5 |

| Manganese (Mn) | ≤ 1.0 |

| Silicon (Si) | ≤ 0.08 |

| Carbon (C) | ≤ 0.01 |

| Sulfur (S) | ≤ 0.03 |

| Phosphorus (P) | ≤ 0.04 |

Mechanical Properties of Hastelloy C276

| Property | Value |

|---|---|

| Tensile Strength | 760 MPa (Min) |

| Yield Strength | 283 MPa (Min) |

| Elongation | 40% (Min) |

| Hardness (Rockwell B) | 89 (Max) |

| Modulus of Elasticity | ~205 GPa |

Packaging & Delivery

- Securely packed in wooden crates, pallets, or wrapped bundles

- Clearly labeled with heat numbers, sizes, and MTCs

- Global shipping with on-time delivery

- All products include relevant documentation: MTC, NDT, PMI, etc.

Why Choose Taashvi Special Alloys for Hastelloy C276 Products?

- Over 20 years of experience in specialty alloys

- In-house testing to ensure top-quality materials

- Ready stock and fast delivery across India and abroad

- Custom machining and sizing based on your exact project needs

- All over India supply capability with full documentation

- ISO-certified processes for consistent quality you can trust

- Dedicated technical support to guide you at every step

When you work with us, you’re not just buying a product, you're getting a partner who understands your challenges and delivers reliable solutions.