Monel K-500

- Other names: Alloy K500

- UNS N05500

Superior Quality in Corrosion Resistance

Taashvi Special Alloys' ALLOY-K500 is the gold standard for high-performance nickel-copper alloys, known for its amazing strength and remarkable resistance to corrosion. This alloy, a precipitation-hardenable nickel-copper superalloy, excels in harsh settings like chemical processing and maritime situations. Because of its unique composition (it contains titanium and aluminum), which provides exceptional resistance to stress corrosion, cracking, and pitting, it is a dependable material for important components under demanding circumstances.

The alloy's superiority is underscored by its impressive characteristics:

01 Corrosion Resistance: ALLOY-K500 excels in resisting corrosion, especially in harsh chemical environments.

02 High Strength: It boasts formidable strength, making it suitable for applications requiring structural integrity under extreme conditions.

03 Resistance to Fatigue: The alloy exhibits excellent fatigue resistance, ensuring long-term reliability in dynamic environments.

04 The non-magnetic attributes: The non-magnetic properties of ALLOY-K500 are retained, increasing its adaptability to a range of applications.

05 Thermal Stability: Its usefulness is increased over a wide temperature range since it maintains its mechanical characteristics at high temperatures.

06 Wear Resistance: The alloy's remarkable resistance to wear extends its useful life under harsh circumstances.

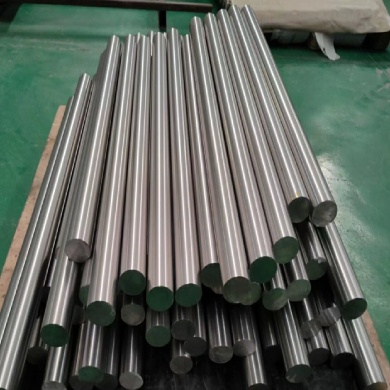

In what forms is Alloy K-500 Available at Taashvi Special Alloys?

- Rod

- Bar

- Forging

- Fasteners

What are the characteristics of Alloy K-500?

- Corrosion resistance in an extensive range of marine and chemical environments. From pure water to non-oxidizing mineral acids, salts and alkalis.

- Excellent resistance to high velocity sea water

- Resistant to a sour-gas environment

- Excellent mechanical properties from sub-zero temperatures up to about 480C

- Non-magnetic alloy

Chemical Composition, %

| Ni | Cu | Al | Ti | C | Mn | Fe | S | Si |

|---|---|---|---|---|---|---|---|---|

| 63.0-70.0 | Remainder | 2.30-3.15 | .35-.85 | .25 max | 1.5 max | 2.0 max | .01 max | .50 max |

In what applications is Alloy K-500 used?

- Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

- Flue gas desulfurization systems

- Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

- Sour gas wells

- Pulp and paper production

- Waste treatment

- Pharmaceutical and food processing equipment

Mechanical Properties

Typical Room Temperature Tensile Properties of Annealed Material

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation | Hardness |

|---|---|---|---|---|---|

| Rod & Bar | Hot-Finished / Aged | 140-190 | 100-150 | 30-20 | 27-38HRC |

| Rod & Bar | Hot Finished / Annealed | 90-110 | 40-60 | 45-25 | 75-90HRB |

| Rod & Bar | Hot Finished / Annealed / Aged | 130-165 | 85-120 | 35-20 | 24-35HRC |

| Rod & Bar | Cold-Drawn / Aged | 135-185 | 95-160 | 30-15 | 25-41HRC |

| Rod & Bar | Cold-Drawn / Annealed / Aged | 130-190 | 85-120 | 30-20 | 24-35HRC |

| Plate | Hot-Finished / Aged | 140-180 | 100-135 | 30-20 | 24-37HRC |

| Sheet | Cold-Rolled / Annealed | 90-105 | 40-65 | 45-25 | 85 HRB Max |

Coil / Sheet /Plate Specification

Dimensions : ASTM, ASME, AISI, DIN, BIS

Thickness : 0.50mm - 100mm

Size : 1000 mm x 2000mm, 1220mm x 2440mm, 4' x 8', 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm

Finish : Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated)

Form : Shim Sheet, Perforated Sheet, Profile Cut,

Seamless & Welded Pipes & Tubes Specification

Specification : ASTM, ASME, DIN, NFA, JIS.

Thickness : 4.0mm - 100mm.

Pipe Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Tube Size : 1/2" OD to 8" OD.

Length : Cut length, Fix length, Single Random, Double Random & Required Length.

Form : Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pancake Coils, Hydraulic Tubes.

End : Plain End, Beveled End, Threaded End.

Type : Seamless & Welded Pipes & Tubes.

Round Bar Specification

Dimensions : ASTM, ASME,AISI, API.

Size : 5 mm to 500 mm

Length : from 2.00mm to 6.35mm (0.078" to 0.25") dia.

Finish : Bright, Black, Polish, Forged

Form : Round Bar, Square, Hexagon

Condition : Cold Drawn & Polished Cold Drawn, Centerless Ground Bars & Polished

Other Services : Machining (CNC), Centerless Grinding (CG), Heat Treatment, Annealing, Pickling, Polish, Rolling, Forging, Cutting, Bending, Minor Fabrication

Seamless & Welded Pipes & Tubes Fittings Specification

Specification : ASTM, ASME, DIN, NFA, JIS.

Size : 1/8” NB to 24” NB, 1/4” OD to 24” OD sizes.

Form : Elbow, Tee, Reducer, Stub End, End Cap, Pipe Nipple, Weldolet,

End : Beveled End, Threaded. Plain End,

Type : Seamless & Welded Pipe & Tubes Fittings, Buttweld Fittings & Dairy Fittings.